WE AIM FOR THE BEST

Premium Seires

GBM Series、OE Premium Meranti LVL、Carbonized Series

Green Building Materials

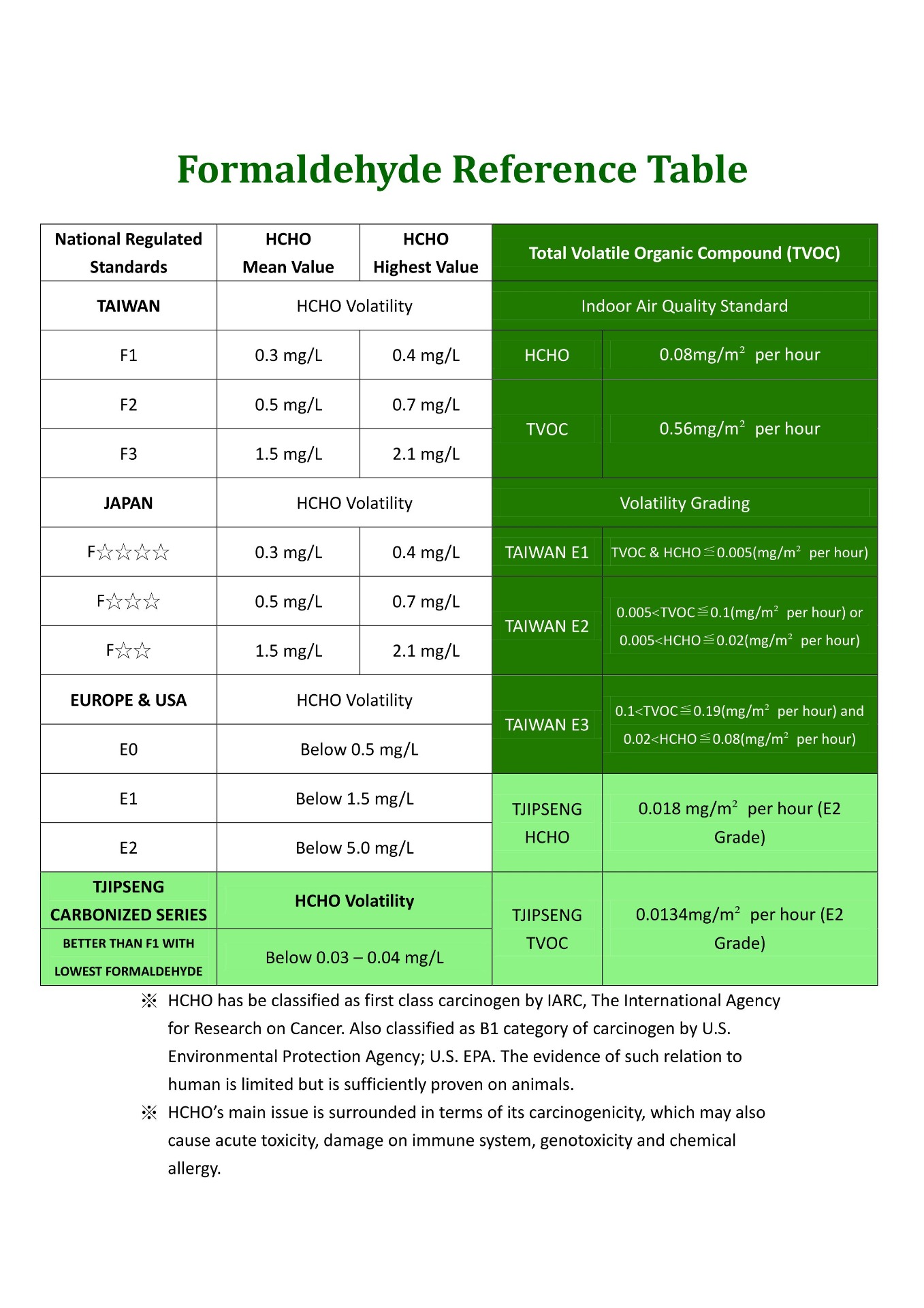

The full name of the certification is " Healthy Green Building Material Certification". The standard was set by referencing the standards from developed countries. With the long term analysis and study from Architecture and Building Research Institute, Ministry of the Interior, the whole standards fits our living nature, weather and environmental condition. Overall takes in measures and controls for TVOC and Formaldehyde in interior decoration use materials.

Other than fulfilling the National Standard CNS 1349, a higher standardization of F1 glue is applied. After examined with TCLP (lead, mercury, hexavalent chromium, cadmium, arsenic, copper, asbestos, radiation, total volatile organic compounds and formaldehyde), GBM is a certification for absolute higher product standard and safety in the use of daily living.

F1 Certification does not equal GBM Certification

There are many firms, designers and carpenters often got mixed up the two certifications and pass on incorrect information to the consumers. Below is the difference identified.

F1 certification covers:

- Conforms with National Standard CNS1349 of low formaldehyde volatility ≦0.3PPM(mg/L).

- As classified,F1 > F2 > F3。F2 standard of formaldehyde volatility ≦0.5PPM(mg/L), F3 standard of formaldehyde volatility ≦ 1.5PPM(mg/L).

GBM certification covers:

- Conforms with National Standard CNS1349 of low formaldehyde volatility ≦0.3PPM(mg/L).

- Also conforms with TCLP Standard (lead, mercury, hexavalent chromium, cadmium, arsenic, copper, asbestos, radiation, total volatile organic compounds and formaldehyde).

- Total Volatile Organic Compound(TVOC)<0.19 mg / m²˙hr

- Formaldehyde(HCHO)<0.08 mg / m²˙hr。

- Does not contain poisonous chemicals listed by Environmetal Protection Administration nor Montreal Protocols.

- The manufacturing factory cannot have penalties by Environmental Protection Administration before or during application for the certification.

- The GBM product should conform with regulated specifications by the National Standard (i.e. moisture content, density etc).

Overall, GBM certification requires to go through a whole set of examinations and lab tests, which F1 certification is only the basic requirement of GBM. Therefore, GBM includes F1 certification but F1 does not equal to GBM. Thus there is also no F2 and F3 allowed in GBM. When having your home interior decoration, it is highly recommended that samples could be taken from construction site and send to national lab for double check.

To distinguish between real or fake certification is not hard. Self-painted spray on the material does not mean that is certified. Real certification will have stickers with full factory information on the side. The number provided on the sticker could be used to check for further information if required.

OE Premium Meranti LVL

This product is exclusive from Chuan Chi in Taiwan, the only pure red meranti F1 LVL in Taiwan. Applied with Europe rotary cut technology, first class red meranti sourced from tropical forests provides the best premium quality for interior decoration. All colors range from dark red to light red.

There are very few factories worldwide that produces pure red meranti LVL. The factories that buy from legal source is even fewer. Red meranti in general only grow 1 centimeter around, and to be able to deforest, it takes 65cm with legal license to obtain. Due to the slow growth rate and forest legislation, the amount for deforestation in Indonesia is limited. Chuan Chi is truly honored to participate and capable to distribute this premium product in Taiwan.

Carbonized Series

Imported from TJIPSENG Corporation. After years of testing in lab and construction sites, we brought you the premium quality of our carbonized series.

Carbonized Characteristics

1. The Reason Behind Carbonization

※As tested, high temperature of 215° C carbonized panel could add more stabilization and durability in long term.

※ Wood contains 50% of cellulose, 23 % of hemicellulose, 20% of lignin and 7% of other organic compounds. Carbonization removes resin within and decreases the moisture content and absorption rate to allow better corrosion resistance. This also means cellulose and hemicellulose has changed their original form and may isolate into furfural and carboxylic acid. This provides durability in long term.

2. Carbonization's Contribution To The Environment

※ The carbonized products are fully adopting plantation forest. During the manufacturing process, best calculated rotary cuts are utilized to increase the usage rate of the logs and minimize any waste possible. With the increased stability and durability in our product, longer lasting in the interior decoration could allow lesser interior renew requirement and extend the forestry life cycle needed for plantation forest.

※ The carbonized products has not just obtained the National Standard and GBM, but is strictly mannered to have be above all those standards available nationally. This breaks the traditional thought in interior design by providing the consumers the best possible materials in the market.

3. Product Characteristics

※ As with the humidity in Taiwan, often low formaldehyde panels would sometime face the problem of mold or insect issues. Now the carbonized panels can truly become no formaldehyde, insect resistant, water resistant and with higher durability, of course, with no chemical added.

※ Double certification from National Standard and SGS has been obtained in all the carbonized product series. We welcome all consumers to try and test our product in daily living and we believe this is the most suitable wood product for every family.